columns

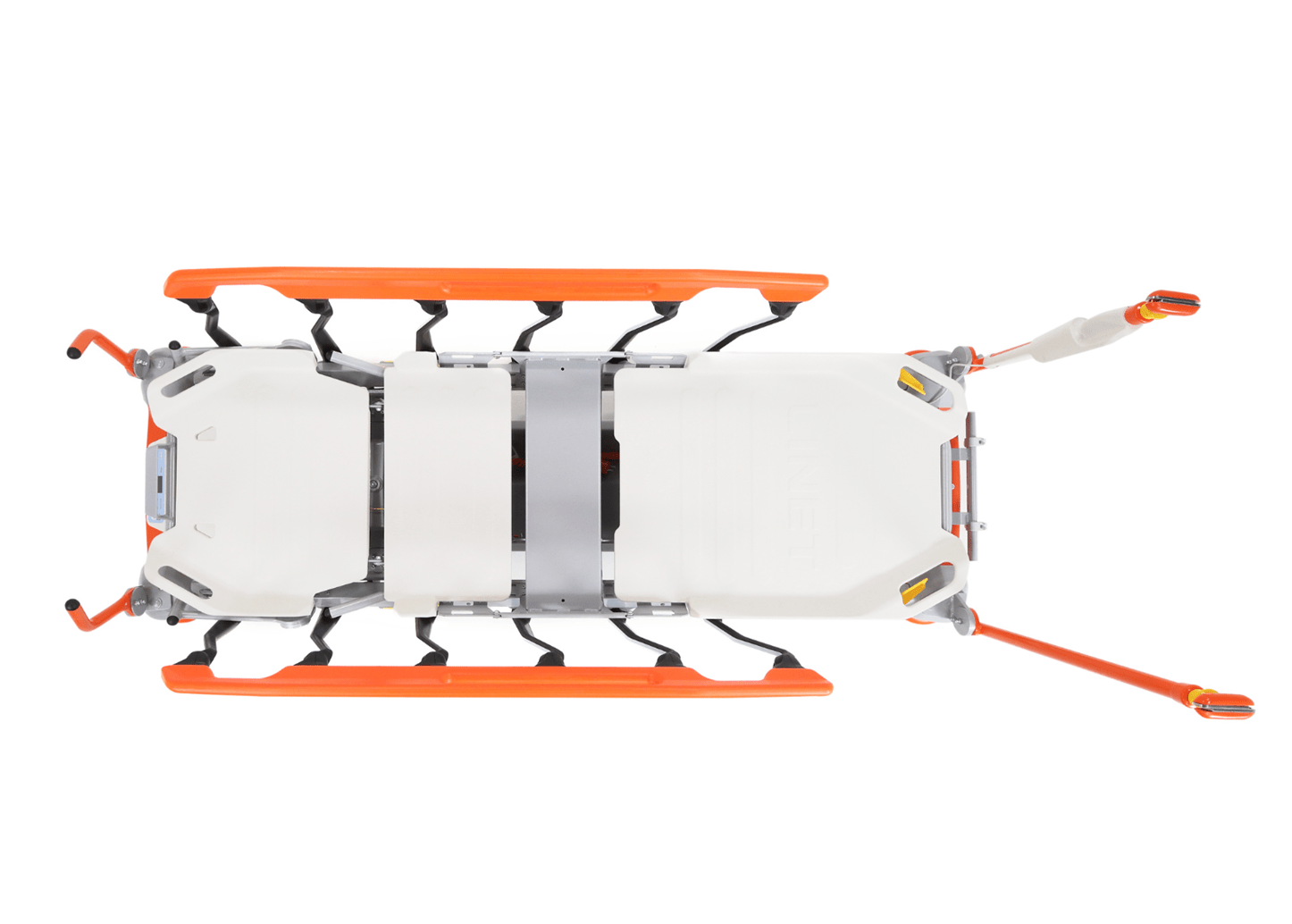

- Columns are smooth and easy to clean

- Accessible undercarriage for cleaning

- Non-corrosive plastic siderails

Go to content | Go to main menu | Go to search

5x

more than recommended force resistance of IV poles thanks to IV&Drive concept(2)

2.2x

more than recommended force resistance of plastic siderails makes them stronger than steel(3)

With columns design, smooth surfaces and accessible undercarriage, the Sprint 200 is easy to clean and maintain.